Home > Sheets > Ricocel® & Risholite® > RICOCEL® Antistatic (ESD) Solder Pallet Material

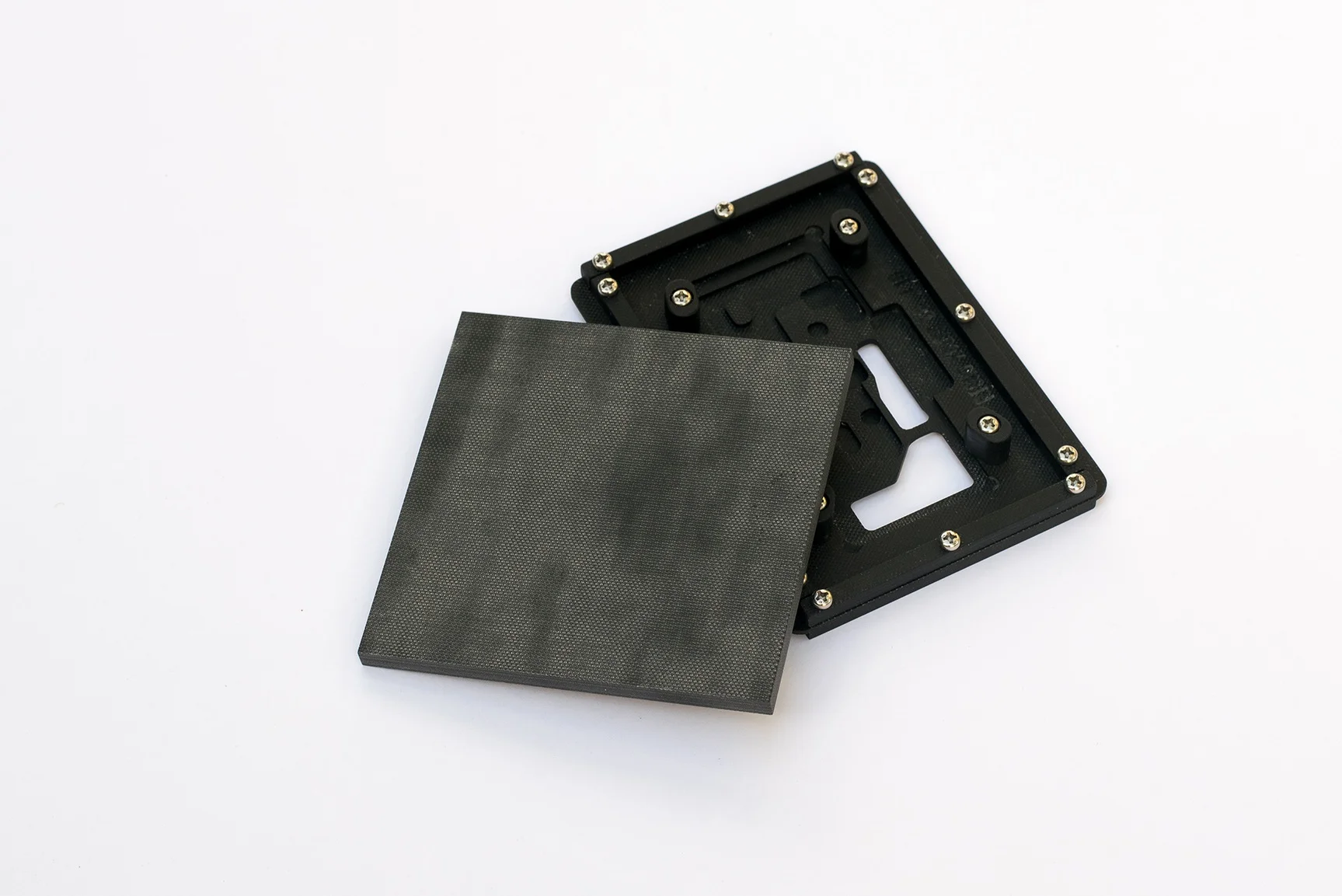

RICOCEL® Antistatic (ESD) Solder Pallet Material

Introduction

RICOCEL® is the industry-leader in Antistatic (ESD) Solder Pallet materials with excellent heat resistance, stable antistatic properties, machinability, durability and flux resistance. Manufactured only in Japan by Risho Kogyo since 2006, RICOCEL® has proven to be one of the most, if not the most reliable, long-lasting, cost-efficient material for making PCB soldering pallets, and it can be found in service at most major CEMs.

RICOCEL® is the preferred Solder Pallet Materials for many companies starting with production operators. Even after many cycles of usage RICOCEL® pallets show very little or no loose fibers that cause discomfort to operators. It is comfortable to handle in the production line and this results in higher operator morale and productivity.

In fabrication, RICOCEL® shows lower tool wear out rates, hence lower tooling costs and higher production efficiency than with other pallet materials. The high mechanical strength of RICOCEL® is a critical feature for very thin walls in the pockets of selective wave soldering pallets, since the pallet is rendered useless once the thin wall breaks. Thus, materials that break easily at thin walls not only increase warranty risks for fabricators, it also increases costs of ownership for end users too.

End users who select RICOCEL® for their pallets benefit from the cumulative productivity and longer pallet life, these far outweigh any perceived cost savings from low cost materials that do not match the reliability of RICOCEL® since fabrication work is the main component and remains the same even if the material is less expensive.

RICOCEL® Antistatic (ESD) Solder Pallet Material

Features

High resistance to most fluxes, produces very little or no loose glass-fibers over prolonged use that can contaminate solder-pot or cause bridging of fine-pitch circuitry.

High mechanical strength for thinner walls in the pockets of selective wave soldering pallets - enables better component shielding, lowers chances of wall breaks which enhances pallet life, thus lowers tooling costs and risk for selective solder pallets.

High temperature tolerance for Lead (Pb)-free Wave soldering and Reflow soldering, over sustained use.

Very stable Electro-Static Dissipative (ESD) property even at soldering temperatures compared to other major brands.

Washable with water and mild detergent or IPA for simple maintenance of pallets.

Good machinability and low wear-out rate of cutting tools compared to other pallet materials.

Applications

Ideal for all types of Soldering pallets - Dip, Wave, Reflow, hand-soldering jigs.

Pallet accessories - component clamps, top-covers, etc.